LinkedIn Insights - June 2021

Andrew Punton | 30-Jun-2021

Don’t miss this tomorrow! There could be some essential information for you if you’re a production or quality assurance #engineer in any of these sectors:

#automotive, #agricultureequipment, #3dprinters, #HVAC, #refrigerationsystems

Clavis | 30-Jun-2021

Don’t miss this, tomorrow! Register here: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

Join Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, for a live video presentation and Q&A. We’ll show you how to achieve better belt measurement and machine performance.

See you there. #webinar #automotive #agriculturalmachinery #3dprinting #engineering

Mark Errington | 30-Jun-2021

It isn’t to late to register! See below.

Event Brite: Setting your belt tension with precision — why use the FourierBMS? #webinaralert

Mark Errington | 30-Jun-2021

What do automotive production lines and HVAC assembly lines have in common? 🤔

They can all benefit from our Fourier Belt Measurement System (BMS).

The FourierBMS is used all over the world to reliably measure belt tension with the highest precision.

Learn more: Webpage: clavis.co.uk/fourier-belt-measurement-system/

#BangOnBeltTension #manufacturing #engineering #automotive #HVAC #OEMs

Clavis | 29-Jun-2021

Don’t miss this on Thursday!

Incorrect tensioning is the most significant cause of drive belt failures, whether in #agriculturalequipment, #automotiveengineering, #HVAC assembly or integrated OEM solutions. In worst cases, it can cause engines to fail completely.

Join Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, for a one-hour live video presentation and Q&A on Clavis’ FourierBMS technology.

We’ll show you how to achieve better belt measurement and machine performance.

Register at Event Brite: Setting your belt tension with precision — why use the FourierBMS?

#webinaralert

Clavis | 29-Jun-2021

With Quality Assurance, what’s more important than traceability?

With so many connections between cars’ technical systems, manufacturers need peace of mind that all the connections are fastened securely.

Fortunately, our Gusto POPP Clamp Release Tool offers 100 per cent traceability. It automatically records each clamp, checking it has closed successfully.

Data is then transmitted wirelessly to the receiver, integrating seamlessly into your data management systems. That’s how you do Industry 4.0!

Learn more about the Gusto here: Webpage: clavis.co.uk/gusto-tool/

#industry40 #innovation

Mark Errington | 29-Jun-2021

Great to see the UK making progress towards widespread electric vehicle adoption!

Whether cars are powered by internal combustion engines or electric batteries, belts usually play an important role in keeping them on the road.

To discuss our belt tension measurement equipment, get in touch: info@clavis.co.uk

Mark Errington | 29-Jun-2021

Don’t forget to register for Thursday’s webinar, below. You can do this at the Eventbrite page. See you on Thursday!

#agriculturalengineering #automotiveengineering #webinaralert

Andrew Punton | 28-Jun-2021

Downtime is frustrating, costly — and avoidable.

This is especially true for process industries. A breakdown in one part of the production line can bring the whole factory grinding to a halt.

Machinery belts keep production lines running. Don’t let incorrect belt tension keep you from meeting your production quotas.

Got any questions? Get in touch with us at info@clavis.co.uk

#manufacturing #engineering #downtime

Clavis | 28-June-21

What’s best for your belt measurement needs — an optical or an acoustic sensor head?

The choice will affect your results, as proper measurement depends on finding the right spot on the belt.

Join Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, for a one-hour live video presentation and Q&A on Clavis’ FourierBMS technology.

We’ll help you make the right choice!

Register at: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

#Webinar #Industry40 #manufacturing #automtoive #agriculturalequipment

Mark Errington | 28-Jun-2021

The possibilities of 3D printing are endless!

Whether you’re printing automotive components or a whole house, correct belt tension plays an essential role in keeping your 3D printer accurate and efficient.

Take a look at the blog I’ve written on the subject:

Article: The future is 3D

#3dprinting #engineering

Clavis | 25-Jun-2021

Electric power-assisted steering. Mobile refrigeration trucks. 3D printers. Agricultural machinery. What do all these applications have in common?

Each one depends on proper belt tension, with incorrect tensioning being the most significant cause of drive belt failures.

Join us for a one-hour live video presentation and Q&A on Clavis’ FourierBMS technology. We’ll show you a how to get optimal belt measurements — and the best machine performance, whatever your application.

Register at: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

#agriculturalequipment #automotiveindustry #3dprintingindustry #webinar #refrigerationsystems

Andrew Punton | 24-Jun-2021

What can you do in 0.3 seconds?

That’s how long it takes our Gusto POPP clamp release tool to check if a hose clamp has been closed correctly. Perfect for busy production environments where every second counts! ⏳

Learn more: Webpage: clavis.co.uk/gusto-tool/

#engineering #innovation #industry40

Clavis | 24-Jun-2021

Did you know that we produce nearly everything in-house? Last year, Clavis moved to a new designed-for-purpose facility in Newcastle-upon-Tyne.

Today, we continue to expand our production capabilities — most recently with a bigger and better, fully-equipped CNC machine.

Our team always strives to deliver the best lead times, quality and accuracy. See for yourself, in this video:

YouTube: New manufacturing and design facility (Build & Move)

#teamwork #engineering #manufacturing

Clavis | 24-Jun-2021

Ideally, industrial belts — in agricultural machinery, automotive, HVAC assembly and other OEM solutions — would vibrate at a single frequency.

But they don’t, which can make taking the best measurements difficult.

Join us for a one-hour live video presentation and Q&A on Clavis’ FourierBMS technology. Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, will demonstrate the technology and algorithms you need to get the best results!

Register at: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

#webinar #engineering #automotive #agriculturalequipment

Andrew Punton | 23-Jun-2021

An interesting read on digital twin technology from Caterpillar Inc.

When using tech to ensure customers have a defect-free experience, don’t forget to measure belt tension!

#manufactuing #industry40

Clavis | 23-Jun-2021

Of course, bespoke is best.

That includes sensor heads used to measure industrial belt vibrations. They must be the perfect size and shape to get in those tight spots, and reach the best spot on the belt.

That’s why we’ve designed and made 50 custom sensor heads, so far.

Make our bespoke equipment integral to your Quality Assurance. Get in touch today: Webpage: clavis.co.uk/contact/

#engineering #innovation

Clavis | 23-Jun-2021

Ideally, industrial belts — in automotive, HVAC assembly and other OEM solutions — would vibrate at a single frequency.

But they don’t, which can make taking the best measurements difficult.

Join us for a one-hour live video presentation and Q&A on Clavis’ FourierBMS technology. Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, will demonstrate the technology and algorithms you need to get the best results!

Register at: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

#webinar #engineering #automotive #agriculturalequipment

Clavis | 22-Jun-2021

What’s best for your belt measurement needs — an optical or an acoustic sensor head?

The choice will affect your results, as proper measurement depends on finding the right spot on the belt.

Join Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, for a one-hour live video presentation and Q&A on Clavis’ FourierBMS technology.

We’ll help you make the right choice!

Register at: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

#technology #automotive #manufacturing #webinar

Mark Errington | 22-Jun-2021

Waste not, want not.

Remanufacturing is an exciting prospect for a sustainable manufacturing future! An interesting report from @JohnDeere.

What other steps should manufacturers take to reduce their environmental impact? 🤔

#manufacturing #remanufacturing #sustainability

Mark Errington | 21-Jun-2021

Are we seeing the death of the manual handbrake? These systems are giving way to new electronic handbrake systems, but they are costly to produce for OEMs.

To reduce costs, micro belt applications are being developed. Read my latest blog, where I explain how proper belt tension in these smaller systems can help OEMs reduce their costs.

#BangOnBeltMeasurement #Engineering #Manufacturing

Andrew Punton | 21-Jun-2021

It’s a great time for innovation in the North East of England!

On a similar note — albeit a slightly smaller scale — check out this video of our new, built for purpose facility in Newcastle-upon-Tyne: YouTube: Build & Move (Extended Version)

#innovation #engineering

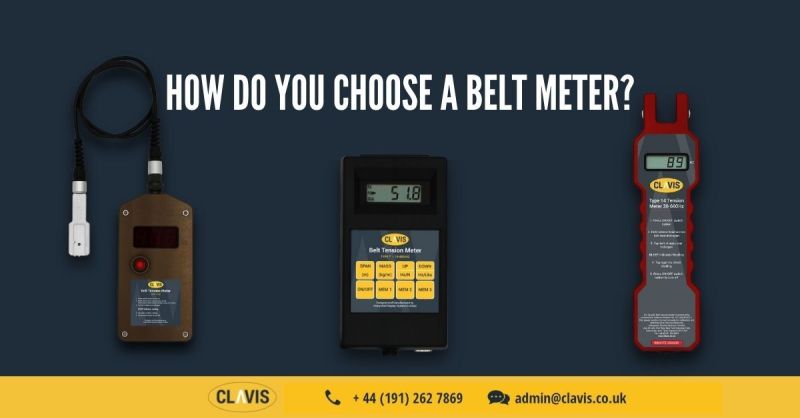

Clavis | 18-Jun-2021

Which Clavis hand-held belt meter is right for you?

All our belt tensioning meters offer accuracy, traceability and reliability. But you should also consider:

⚙ Belt size

⚙ Belt thickness

⚙ Unit of measurement

⚙ Production conditions

Learn more: Webpage: clavis.co.uk/hand-held-belt-meters/

#engineering #BangOnBeltMeasurement

Clavis | 17-Jun-2021

Are you an OEM looking for a way to measure belt tension?

Then our Fourier BMS is designed for you!

Used for quality checking and assembly in plants worldwide, the Fourier BMS can make your production processes more efficient, consistent and profitable.

It’s also accurate, measuring vibrational frequencies between 30 Hz and 500 Hz on a wide range of belts. Learn more, here: YouTube: FourierBMS – Belt Measurement System

#OEM #BangOnBeltTension

Clavis | 17-Jun-2021

Clavis has developed a closed-loop system that measures, monitors and accurately controls industrial belt tension measurement from start to finish.

This results in more reliable and repeatable performance — and better engine performance.

Join Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, for a one-hour live video presentation and Q&A on Clavis’ FourierBMS technology.

Get in the loop!

Register at: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

#manufacturing #quality #testing #automotive #webinaronline

Clavis | 16-Jun-2021

Incorrect belt tension is the biggest cause of belt failure. In the worst cases, it can cause complete engine shutdowns.

Too much tension results in stress on the belt, bearings and shafts. Too little causes slippage, excess heat and premature belt and pulley wear.

To the balance just right, you should look to our range of accurate and reliable belt meters: Webpage: clavis.co.uk/products/

#BangOnBeltTension #BangOnBeltMeasurement #automotive

Mark Errington | 16-Jun-2021

From tractor engines, to combine harvester conveyors and grain dryers, belts play a part in every step of arable farming.

Harsh conditions, challenging weather and long hours put these machines through their paces each year. Breakdowns are a normal part of life on the farm — but they don’t have to be.

For machinery that runs longer, faster and more efficiently, you must ensure that agricultural belts are correctly tensioned with our accurate and reliable belt tension measurement equipment.

Contact us to find out more: Webpage: clavis.co.uk/contact/

#agriculture #BangOnBeltTension

Clavis | 15-Jun-2021

Q: What’s the most common cause of industrial drive belt failures?

A: Incorrect tensioning.

In worst cases, it can cause engines to fail completely.

That’s why — whether you’re involved with automotive production lines, HVAC assembly or integrated OEM solutions — you won’t want to miss our next webinar.

Register at: Event Brite: Setting your belt tension with precision — why use the FourierBMS?

Join Mark Errington, director at Clavis, and Pavlos Sgardelis, product specialist at Clavis, for a live video presentation and Q&A. We’ll show you how to achieve better belt measurement and machine performance.

#webinar #automotive #manufacturing #quality #engineering

Clavis | 10-Jun-2021

Why settle for off-the-shelf?

At Clavis, we pride ourselves in understanding our customers’ needs.

That means producing the highest-quality bespoke belt tension measurement systems, and automotive handbrake setting equipment.

Our technology also stands-up to the busiest production environments.

If you need a system that’s designed especially for your, then get in touch with our specialists today: Webpage: clavis.co.uk/contact/

#BangOnBeltTension #automotive #engineering

Mark Errington | 10-Jun-2021

Want to reduce risks of joint leakage or hose blow-off in car engines?

Then try our Gusto POPP Clamp Release Tool, which error proofs hose installation traceably, wirelessly and reliably.

Watch the video below.

#engineering #innovation #industry40

Clavis | 9-Jun-2021

STOP! Or can you?

Working brakes are essential for keeping drivers and the people around them safe. So, setting them correctly is a big responsibility.

Our brake setting equipment is sensitive, accurate and precise. It is custom-designed to fit each brake it’s used on — and takes less than 20 seconds.

Learn more: Webpage: clavis.co.uk/handbrake-setting/

#automotive #engineering

Clavis | 8-Jun-2021

In his debut article, Pavlos Sgardelis, senior engineer at Clavis, breaks down why wireless tools are the future for busy production environments.

They offer:

✔ Traceability

✔ Flexibility

✔ Ease of installation

Read it below.

Article: No More Wires

#industry40 #engineering #manufacturing

Andrew Punton | 3-Jun-2021

Want to measure belt tension accurately and reliably?

Our FourierBMS closed loop system:

✔ Reduces errors

💪 Improves stability

💫 Increases reliability and repeatability

Watch the video below for more on the FourierBMS closed loop system.

#BangOnBeltTension #engineering

Clavis | 3-Jun-2021

Full traceability, quality control, efficiency — all things vehicle parts manufacturers strive for.

Fortunately, Clavis’ Gusto POPP Clamp tool offers all this and more in just 0.3 seconds.

How? See more in this video: YouTube: Give It Some Gusto

#giveitsomegusto #manufacturing #automotive #engineering #innovation

Want to know more?

Check out this video explaining steer-by-wire for automatic emergency steering! Nice one, Nexteer Automotive.

Did you know, correct belt tension is vital for steer-by-wire systems, so that even slight movements of the steering wheel are translated to the wheels.

#engineering #steerbywire